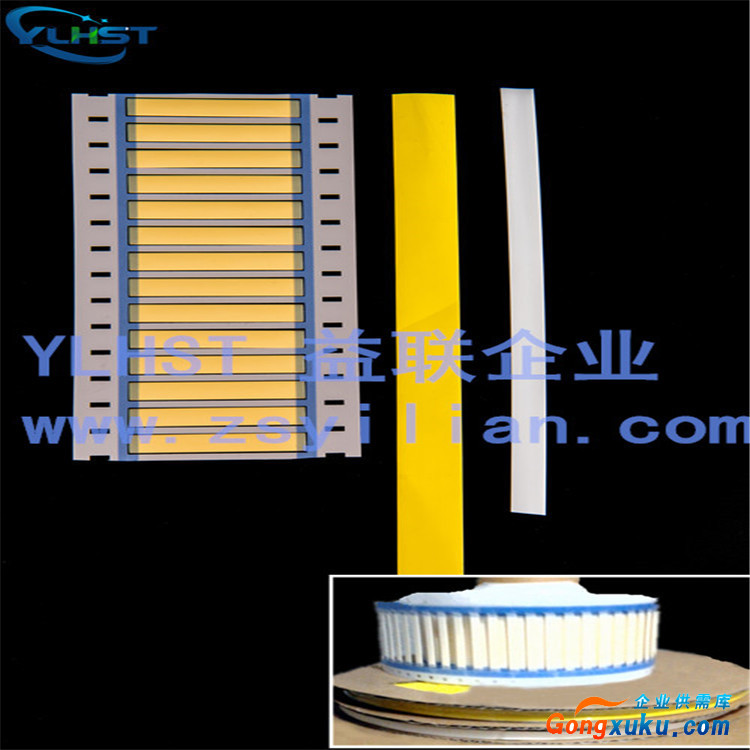

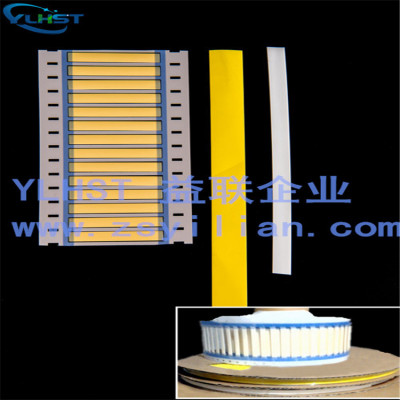

TMS125 低烟无卤阻燃聚烯烃热收缩标识套管

应用

低烟无卤阻燃聚烯烃热收缩标识套管是专为电线电缆标识而设计,由辐照交联低烟无卤阻燃聚烯烃材质制成,具有优异的电气性能、物理性能、化学性能和打印性能,可以方便地用标识打印直接打印,标识持久。不仅符合ROHS和REACH环保指令,而且符合IEC61249-2-21、欧盟2002/72/EC等环保标准的要求。

特性

收缩比:3:1,2:1

柔软、低烟无卤阻燃

可以方便打印

优异的打印性能,持久标识,符合SAE AS81531的打印标识要求

优异的电绝缘性能、物理性能和化学性能

符合ROHS、REACH环保规范

颜色

标准颜色:白色、黄色

其他颜色可定制

操作温度范围

连续使用温度范围:-55℃~125℃

起始收缩温度:70℃

完全收缩温度:110℃

符合标准

SAE AS 81561,MIL-STD-202

UL224 125℃ 600V

性能指标

性能 | 指标要求 | 测试方法 | 典型值 |

纵向收缩率 | ≤10% | ASTM D 2671 | ≤5% |

抗张强度 | 10.4MPa min | ASTM D 638 | ≥12MPa |

断裂伸长率 | 200% min | ASTM D 638 | ≥300% |

老化后断裂伸长率 (热老化158℃,168小时) | 100% min | ASTM D 638 | ≥200% |

热冲击

| 无裂纹 | ASTM D 2671 | 无裂纹 |

低温柔软性 (-55℃,4小时) | 无裂纹 | ASTM D 2671 | 无裂纹 |

绝缘耐压和击穿 | 2500V,60sec,不击穿 | ASTM D 2671 | 不击穿 |

击穿强度 | 19.7 KV/mm min | ASTM D 2671 | ≥20KV/mm |

体积电阻率 | 1014Ω•cm min | ASTM D 876 | ≥1014Ω•cm |

腐蚀性 | 无腐蚀 | ASTM D 2671 | 无腐蚀 |

阻燃性 | 1分钟内自熄 | ASTM D 2671 | 通过 |

打印性能 | 50次橡皮擦,可辨认 30次来回擦,可辨认 | SAE SA81531 MIL-STD-202 | 通过 |

抗液体 (23℃,24小时) | 打印吸识别 | SAE AS81531 | 通过 |

规格尺寸

规格 | 收缩前(mm) | 完全收缩后(mm) | 适用线缆范围(mm) | |

英制 | 公制 | 内径(min) | 内径(max) | |

3:1 | ||||

3/32 | Ф2.4 | 2.4 | 0.8 | 0.9~2.0 |

1/8 | Ф3.2 | 3.2 | 1.1 | 1.1~2.7 |

3/16 | Ф4.8 | 4.8 | 1.6 | 1.8~4.1 |

1/4 | Ф6.4 | 6.4 | 2.1 | 2.3~8.1 |

3/8 | Ф9.5 | 9.5 | 3.2 | 3.5~8.1 |

1/2 | Ф12.7 | 12.7 | 4.2 | 4.6~10.8 |

3/4 | Ф19.1 | 19.1 | 6.3 | 7.0~16.3 |

1 | Ф25.4 | 25.4 | 8.5 | 9.3~21.6 |

2:1 | ||||

3/32 | Ф2.4 | 2.4 | 1.2 | 1.3~2.3 |

1/8 | Ф3.2 | 3.2 | 1.6 | 1.7~3.1 |

3/16 | Ф4.8 | 4.8 | 2.4 | 2.5~4.7 |

1/4 | Ф6.4 | 6.4 | 3.2 | 3.3~6.3 |

3/8 | Ф9.5 | 9.5 | 4.8 | 4.9~9.0 |

1/2 | Ф12.7 | 12.7 | 6.4 | 6.6~12.0 |

3/4 | Ф19.1 | 19.1 | 9.5 | 10.0~18.5 |

1 | Ф25.4 | 25.4 | 12.7 | 13.0~24.5 |

11/2 | Ф38.1 | 38.1 | 19.1 | 21.0~37.0 |

2 | Ф50.8 | 50.8 | 25.4 | 27.0~48.0 |

其他规格尺寸可定制

TMS125 Halogen Free Heat Shrinkable Polyolefin Identification Sleeve

Application

Special designed to meet the requiremwnts of identification of wire and cables. It is made of halogen-free flame retardant polyolefin with excellent electrical, physical, chemical and printing properties. It can be printed by market printed with permanent identification. TMS125 meets the requirement of ROHS, REACH, IEC61249-2-21 and EU2002/72/EC standards.

Characteristics

Shrink ratio: 3:1, 2:1

Flexible, Halogen-free flame-retardant.

Easy to be print.

Excellent printing property, permanent identification, SAE AS81531 applicable.

Excellent electrical, physical, chemical and printing properties.

ROHS and REACH compliant.

Color

Standard color: White, yellow

Other colors are available upon request.

Operating Temperature Range

Operating temperature: -55℃~125℃

Minimum shrink temperature: 70℃

Minimum fully recovery temperature: 110℃

Approvals

SAE AS 81561,MIL-STD-202

UL224 125℃ 600V

Property

Property | Requirement | Test method | Typical data |

Longitudinal shrinkage | ≤10% | ASTM D 2671 | ≤5% |

Tensile strength | 10.4MPa min | ASTM D 638 | ≥12MPa |

Elongation at break | 200% min | ASTM D 638 | ≥300% |

Elongation after aging (158℃,168hrs) | 100% min | ASTM D 638 | ≥200% |

Heat shock

| No crack | ASTM D 2671 | No crack |

Low-temperature flexibility(-55℃,4hrs) |

No crack |

ASTM D 2671 |

No crack |

Dielectric voltage withstand | 2500V,60sec,no breakdown | ASTM D 2671 | No breakdown |

Dielectric strength | 19.7 KV/mm min | ASTM D 2671 | ≥20KV/mm |

Volume resistivity | 1014Ω•cm min | ASTM D 876 | ≥1014Ω•cm |

Corrosion | No corrosion | ASTM D 2671 | No corrosion |

Flammability | Self-extinguishing within one second | ASTM D 2671 | Pass |

Printing performance | 50rubs, legible 30strokes, legible | SAE SA81531 MIL-STD-202 | Pass |

Fluid resistance(23℃,24hrs) | Printing legible | SAE AS81531 | Pass |

Sizes

Size | As supplied (mm) | After recovered(mm) | Recommended use range (mm) | |

inch | mm | Inside diameter(min) | Inside diameter (max) | |

3:1 | ||||

3/32 | Ф2.4 | 2.4 | 0.8 | 0.9~2.0 |

1/8 | Ф3.2 | 3.2 | 1.1 | 1.1~2.7 |

3/16 | Ф4.8 | 4.8 | 1.6 | 1.8~4.1 |

1/4 | Ф6.4 | 6.4 | 2.1 | 2.3~8.1 |

3/8 | Ф9.5 | 9.5 | 3.2 | 3.5~8.1 |

1/2 | Ф12.7 | 12.7 | 4.2 | 4.6~10.8 |

3/4 | Ф19.1 | 19.1 | 6.3 | 7.0~16.3 |

1 | Ф25.4 | 25.4 | 8.5 | 9.3~21.6 |

2:1 | ||||

3/32 | Ф2.4 | 2.4 | 1.2 | 1.3~2.3 |

1/8 | Ф3.2 | 3.2 | 1.6 | 1.7~3.1 |

3/16 | Ф4.8 | 4.8 | 2.4 | 2.5~4.7 |

1/4 | Ф6.4 | 6.4 | 3.2 | 3.3~6.3 |

3/8 | Ф9.5 | 9.5 | 4.8 | 4.9~9.0 |

1/2 | Ф12.7 | 12.7 | 6.4 | 6.6~12.0 |

3/4 | Ф19.1 | 19.1 | 9.5 | 10.0~18.5 |

1 | Ф25.4 | 25.4 | 12.7 | 13.0~24.5 |

11/2 | Ф38.1 | 38.1 | 19.1 | 21.0~37.0 |

2 | Ф50.8 | 50.8 | 25.4 | 27.0~48.0 |

Other sizes are available upon request.